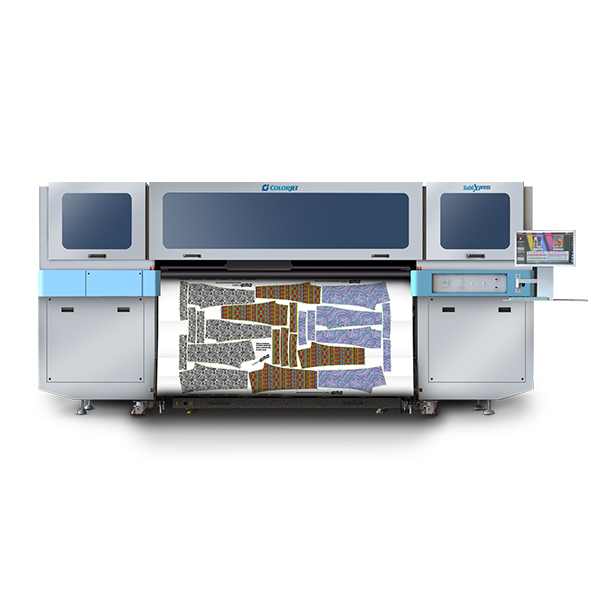

Colorjet Sublixpress

In stock

Share:

OVERVIEW

High-Speed Sublimation Printer

SubliXpress is a high-speed sublimation machine and a game-changer in the business of industrial sublimation printing machine. This dye-sublimation printer is India's fastest ROI 1.6 m sublimation machine. Equipped with up to 4 industrial-quality Kyocera print-heads, it prints variable ink-jetting intensities between 4-72 PL. The polyester fabric printing machine offers the capacity of 4000 sq. m/day. It enables the textile print businesses to obtain high volume output with a single high-speed sublimation machine. Its industrial feed and take-up system supports diameter roll of up to 400 mm. This sublimation paper transfer machine comes with an advanced ink degassing system to eliminate any kind of bubbles inside the ink giving the print a smooth finish. Low power consumption is one of the advantages of the dye-sublimation printer making it an eco-friendly polyester fabric printing machine. SubliXpress, the high-grade industrial sublimation printing machine comes with infrared dryers for instant drying. This high-speed sublimation machine comes preloaded with advanced Colorjet edition of the RIP software with colour management engine and colour processing tools. It offers fabric specific ICC profile for smooth gradations and vibrant colours for superior print quality.

PRIME BUSINESS REASONS TO BUY

INDIA'S FASTEST ROI SUBLIMATION PRINTER

- Up to 4Kyocera Head

- Multiple Drying System

- AST - Active Seaming Technology

- Super Powerful Vacuum bed

- TST - Transducer Sensor Tech for low GSM paper handling

- Industrial Feeding & Take-up Roller with Airshaft

FEATURES

SubliXpress is an industrial high-speed sublimation machine that comes with Jumbo Roll Feeder, Infrared dryers and is equipped with handling thin paper to as low as 20 GSM which provides high ink transfer rates. With a capacity of printing 4000 sq. meter per day, this single machine has enabled to replace almost six old technology sublimation machines. The TST technology (Transducer Sensor Tech) has been inbuilt in the machine to provide effective synchronization of the paper movement during winding and unwinding. It is also equipped with Anti Crash Sensor for accurate detection of media unevenness. In order to eliminate the bubble inside the ink and to avoid any ink starvation during printing, there is an ink degassing system and self-adjusting negative pressure. Dual Rail setup has been provided to achieve higher precision jetting and sturdiness to the printer carriage, leading to low maintenance. Accurate media feeding is important and hence SubliXpress comes with a Powerful Variable Vacuum Bed. The machine is built with a solid Aluminium Frame to eliminate vibration, guaranteeing stable print, and long life.

- ANTI CRASH SENSOR : For accurate detection of media unevenness

- INK DEGASSING SYSTEM & SELF ADJUSTING NEGATIVE PRESSURE : To eliminate the bubble inside the ink,to avoid any ink starvation during printing.

- AUTOMATIC CAPPING AND WIPING SYSTEM : To ensure continuous production, and for a possible ink reuse.

- PRINTING TECHNOLOGY : Variable drop Inkjet from 4pl to 72pl with Kyocera print Head.

- TST (TRANSDUCER SENSOR TECH) : To effectively sync the paper movement during winding and unwinding

- DUAL RAIL : To provide higher precision jetting and sturdiness to the printer carriage, effectively leading to lower maintenance.

- POWERFUL VARIABLE VACCUM BED : For accurate media feeding

- SOLID ALUMINIUM FRAME : Eliminates vibration, guaranteeing stable print and long life.

- PRE HEATER : IR rods for instant heat with low power consumption to media

- POST HEATER : Infrared dryer with blower to provide precise ink absorption on the media for excellent results.

- DANCING ROLLER : To provide continuous tension and roll alignment

- TAKE-UP & FEEDER ROLLER : Supports upto 400mm diameter with air shaft.

SPECIFICATION

SubliXpress works on the technology of Drop-on-demand, Piezoelectric Inkjet that prints up to the high quality of 600x2400 DPI with the option of 4 colours and upto 4 print heads. It is a high-speed sublimation machine with speed going up to 210 sq. meters per hour. It offers the convenience of varied file formats including JPEG, TIFF, BMP, PDF (RGB/CMYK). Dye sublimation aqueous based inks are used in the refillable ink system of SubliXpress. ColorJet edition of Onyx, RIP software is supported.

SubliXpress |

|||||

|

Models

|

X4406

|

X4203

|

|||

| Printing Technology |

Drop-on-demand, Piezo Electric Inkjet

|

||||

| No. of Print Heads |

4

|

2

|

|||

| Print Heads | Type |

Industrial Grade Jetting Assemblies

|

|||

| Resolution |

Upto 2400 dpi

|

||||

| Height Adjustment |

Upto 20mm

|

||||

| Cleaning Method |

Pressure Purge and Wiping

|

||||

| Wetting Control |

Piezoelectric actuations

|

||||

| Inks | Types |

Dye Sublimation Aqueous based Inks

|

|||

| No. of Color |

4

|

4

|

|||

| Supply |

Refillable

|

||||

| Media | Max. Thickness |

Upto 20 mm

|

|||

| Max/Printing Width |

Upto 1650 mm

|

||||

| Roll Daimeter |

400 mm

|

||||

| Distance Accuracy |

Error of less than +0.3 % of distance travelled, or +0.3 mm, whichever is greater

|

||||

| Media Drying System |

Infrared Heaters

|

||||

| Printing Interface |

USB 3.1

|

||||

| Rip Software Supported |

Onyx(ColorJet Edition)

|

||||

| File Format |

JPEG/TIFF/BMP/PDF (RGB/CMYK)

|

||||

| Power Requirements(Print Engine) |

AC 220 V, 43 A, 50/60 Hz

|

||||

| Power Requirements(Dryer) |

AC 220 V, 20 A, 50/60 Hz

|

||||

| Dimensions (Printer Only) |

3775 x 1600 x 1830 mm

|

||||

| Dimensions (With Packing) |

3875 x 1470 x 2100 mm, 4180 x 880 x 1340 mm

|

||||

| Weight |

N.W.1450 Kg, G.W.1600 Kg

|

||||

| Operating Conditions |

Temperature: 20 to 28℃ Humidity: 50 to 65%RH (non-condensing)

|

||||

| Speed(In Sq.Meter/Hr) |

Print DPI

|

Passes

|

X4406

|

X4203

|

|

| Mode 1 |

600 x 600

|

1

|

210

|

-

|

|

| Mode 2 |

600x1200

|

2

|

123

|

-

|

|

| Mode 3 |

600x1800

|

3

|

88

|

-

|

|

| Mode 4 |

600x2400

|

4

|

68

|

-

|

|

| Mode 5 |

600x300

|

1

|

-

|

182

|

|

| Mode 6 |

600x600

|

2

|

-

|

128

|

|

| Mode 7 |

600x900

|

3

|

-

|

81

|

|

| Mode 8 |

600x1200

|

4

|

-

|

61

|

|

APPLICATIONS

SubliXpress is the go-to sublimation printing machine for a variety of applications. This polyester fabric printing machine also prints on most other types of fabrics. Apart from being used as a sports apparel printing machine, this sublimation paper transfer machine is also used for various other applications like, fashion apparels, home furnishings, personalised merchandise, sports gear, etc.

Returns Policy

Unopened, Unused items are applicable for returning within 30 days. Buyer pays return shipping. You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the 'Complete Orders' link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.